Some automotive units, such as a motor, gearbox, clutch, are wrapped in a housing, also called a crankcase. It protects the internal elements from damage, stores oil and simply serves as a platform for attaching individual parts of the device. About what crankcases can be in the car - further in the review.

Who invented carter

This device owes its appearance to the Englishman John Harrison Carter. This engineer invented the Sunbeam bike chain housing in 1889, which became the first crankcase. Such a product stored oil, and also protected the bicycle chain from unwanted influences.

Over time, the crankcase found its application in automotive technology, becoming, one might say, an integral part of it. Such parts are used on almost all parts of the machine that use oil. Well, first of all on the motor.

Car engine crankcase

Basically, under the concept of "crankcase" motorists mean exactly the motor housing. This shell covers the cylinder block, the various shafts and contains the oil sump. However, the design of the engine cover is largely dependent on the size of the power unit itself.

In not too large engines, the body assembles the parts into a common unit and is made in the form of a cast product - a block crankcase. Often it also includes cylinder liners.

In addition, the housing of a light 2-stroke engine containing several cylinders can be divided into sealed blocks, as is the case with Wartburg, Trabant or DKW vehicles. These compartments are linked to their cylinders through personal channels. With this design, the power unit is lubricated with a "two-stroke mixture" added to the fuel.

But already for motors with medium dimensions, casting the crankcase as a single product is not so easy, and even for large ones. Unsurprisingly, large power plant housings are usually assembled from separate parts, connected by fasteners or simply welded. Moreover, in such units, the volume of the cavity sometimes reaches several cubic meters!

In addition, in engines of the middle category, and even more so in "heavyweights" such as Sulzer, DKRN, Burmeister & Wain, a design with a separate container for oil, called a "dry sump", has found its application. Sports cars and cool SUVs are equipped with engines of just this kind.

Some motorcycles also have a dry crankcase. A similar design is used when it is problematic to place a large oil pan in the motor housing, or on models designed for off-road, as well as enduro racing. Even if such a "bike" is lying on its side, its motor will not lack oil.

What is the crankcase made of

Mostly aluminum alloy or steel. Previously, cast iron was actively used, now it is a rarity. On some European cars, there are even crankcases with heat-resistant plastic elements. Sometimes, in order to increase the rigidity of the structure, the motor housing is supplemented with ribs.

The oil pan is also cast from aluminum or made of steel by stamping. Moreover, such a container, made of aluminum, cools the engine better, but at the same time has a higher cost, is less durable and is poorly repairable. By the way, used oil is drained from the crankcase through a special plug located on it.

Transmission housings

However, the engine body - if it is the main one, then, as a rule, is not the only crankcase that is part of the car. Modern cars usually have several of these products, and most of them relate to the transmission. In particular, to the following elements:

- Checkpoint;

- clutch;

- driving axle;

- transfer case.

Each of the crankcases of this group has its own purpose and design features. However, if you do not take into account the housing of the clutch system, you can designate elements common to all these products:

- the filling part through which the lubricant is introduced;

- device for draining unnecessary grease;

- a breather that brings the pressure in the crankcase to atmospheric pressure, thereby preventing oil from leaking at the joints when this indicator is too high, caused by the high temperature of the body.

- holes for shafts and seals.

Carter gearbox and transfer case

This is the gearbox cover, and for all-wheel drive cars - also the transfer case. One of its main purposes is to provide these devices with a lubricant.

At present, cast iron or aluminum products, made as a whole, prevail among the shells of these devices. Such crankcases can be divided into 2 types, based on the location of the cover:

- top of the product;

- the end on the other side of the clutch.

The placement of the lid on top is inherent in old boxes, while for modern ones it is typical to find it on the side. Mechanical transmissions with this design are now often installed on trucks. Moreover, some trucks are equipped with separate clutch, splitter and gearbox housings. Well, the crankcase of the "machine" is often combined with a similar part of the torque converter.

And on the gearbox housing there are areas for connecting a device that switches speeds, as well as various sensors, in particular, one connected to a speedometer.

Clutch housing

There is only one dry sump in the transmission and that is the clutch housing located between the engine and the gearbox. During the normal operation of the vehicle, this product should not contain any oil or other liquid substances.

On this case, devices can be installed for monitoring the clutch and adjusting it, however, this is not always the case. And in cars with an automatic gearbox, the clutch cover is replaced with a similar part for the torque converter.

Drive axle housing

This product combines the main gear, the inter-wheel, and for three-axle trucks - the center differential, wheel gears and wheel gears, if any. There are 2 main types of bridge casings:

- Split, or split - consisting of two cast parts connected vertically. It is typical of old cars, although it is still installed on UAZs and a number of Russian medium-tonnage trucks.

- One-piece, typical of modern cars. One or two of its sides are covered with stamped covers, which can be located in the front, back or bottom of the case.

In this case, bridge beams, called "stockings", are either independent parts pressed into the body, or form a single product with it.

The latter type of casing is called "banjo" because of its similar shape. Well, in some bridges - for example, in UAZs, in a number of trucks and vehicles with high off-road qualities, the crankcase has a 3-in-1 formula. This includes the central case of the final drive and differential, plus two more - wheel reduction gears.

Crankcase Care

The oil pan of the engine crankcase is located close to the surface of the track, so it can be easily deformed with the help of objects in the way, or irregularities on the road. The consequences are as follows: oil flows out of the engine, the camshaft and crankshaft bearings remain without lubrication. Continued driving in such conditions is fraught with wear and seizure of the plain bearings.

To avoid such a nightmare, a crankcase protection made of high strength metal or a composite substance is mounted under the car engine.Such a part is attached to the body side members and reliably protects the crankcase from contact with stones, curbs or "speed bumps".

Sometimes such devices are equipped with holes that open the way to the drain plug, as well as hatches that make it possible to replace the oil filter. In addition, the protective plate makes it difficult for ill-wishers to access the engine compartment, thereby reducing their chances of car theft.

If, however, a crack has nevertheless appeared in the sump of the engine, then this defect can be tried to be corrected by welding, electric or gas for steel cases, and also exclusively argon for aluminum ones. You can also find special sealants for pallets in stores, but such products are likely to be effective only until the next blow.

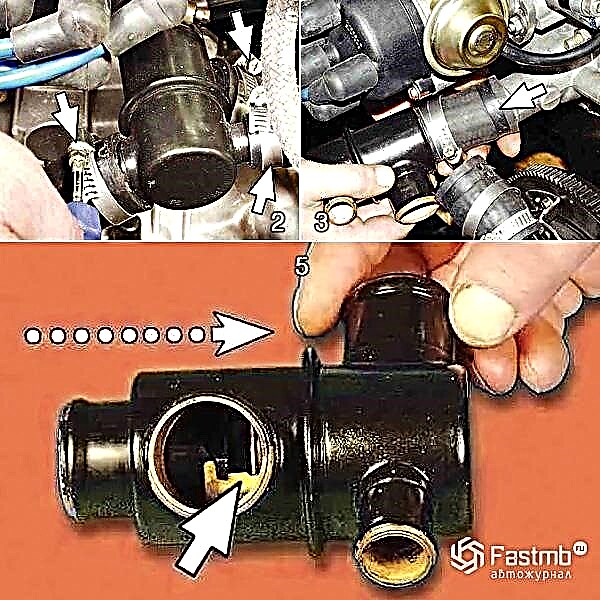

In extreme cases, it may be necessary to replace the pallet, which, however, is not a daunting task. To do this, the old oil is drained, if it has not yet flowed out through the hole, the fastening bolts are removed and a new sump is mounted. By the way, if you change the pallet, then together with it it is desirable to replace its gasket.

As for the transmission housings, they are cast from metal or stamped products, and, moreover, maintenance of these covers is minimal. But in order so that they perform their functions efficiently, car owners should still:

- make sure that oil does not flow through the joints of the crankcase, which can also be indicated by oil traces under the car when the vehicle is in one place for a long time;

- timely identify possible damage to crankcases;

- depending on the car model and operating conditions, clean or flush the breathers every 4-15 thousand km of driving;

- when draining used oil, clean the drain plug from dirt and metal shavings.

If the crankcase has been disassembled, then during its subsequent assembly, the bolted connections should be given the degree of tightening provided for in the instructions. It is also sometimes necessary to install new gaskets on the body. The degree of reliability of fastening the product itself to the bearing surface of the machine is also important.

In general, transmission crankcases are distinguished by their endurance and long service life, so they rarely burden motorists with unnecessary troubles.

Conclusion

Carters are different, and they all require care, although they differ in the degree of complexity. The oil pan is considered to be the most vulnerable part of the engine body and therefore needs special care. Transmission housings are reliable in themselves, but motorists should not forget about them either.

|| list |

- Who invented carter

- Car engine crankcase

- What is the crankcase made of

- Transmission housings

- Carter gearbox and transfer case

- Clutch housing

- Drive axle housing

- Crankcase Care